Ever strolled down the grocery aisle and spotted a mysterious symbol resembling a flower inside a circle on a food package? That’s the radura, and it signals that the product has been gamma processed. If you’re like most people, your first thought might be, “Gamma processed? Sounds like something out of a sci-fi movie!” And you wouldn’t be entirely wrong. It involves radiation, but don’t worry, it’s not going to turn your food into a glowing green monster.

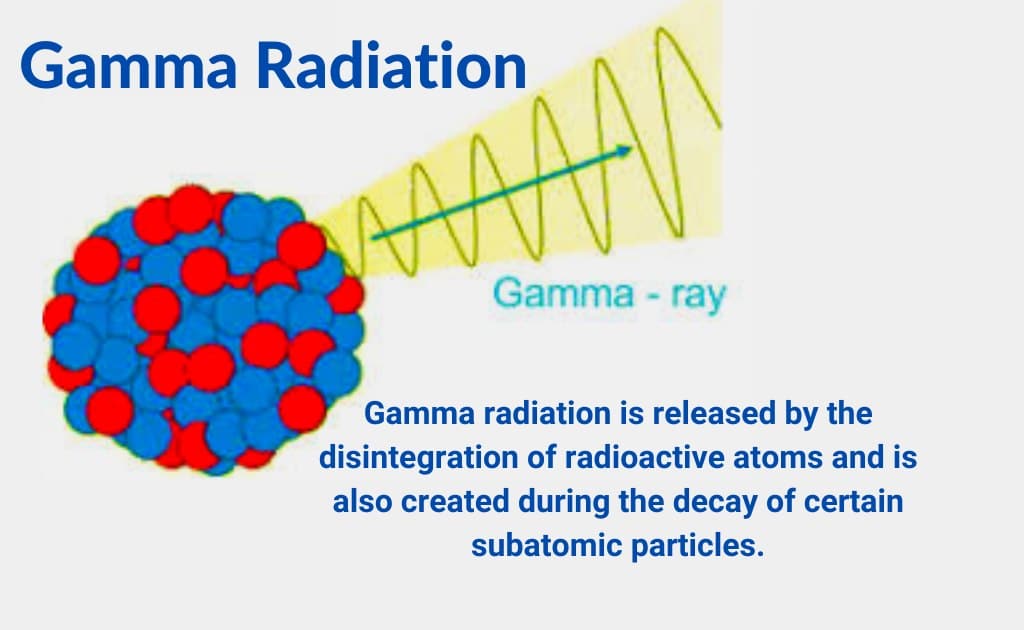

So, what exactly is gamma processing? It all starts with gamma rays. Imagine the electromagnetic spectrum, that rainbow of energy that includes everything from radio waves to visible light. Gamma rays sit on the far end of this spectrum, possessing the highest energy and shortest wavelengths. They’re a form of ionizing radiation, which means they have enough energy to knock electrons off atoms, a process that can be used to kill bacteria, insects, and parasites. Think of them as tiny, incredibly powerful bullets targeting those microscopic baddies that can make us sick or spoil our food.

These gamma rays typically originate from radioactive isotopes, like Cobalt-60 or Cesium-137. Now, before you picture a glowing vat of radioactive goo, it’s important to understand that these isotopes are carefully contained and shielded. They emit gamma rays, which are then used to treat the food. The food itself never comes into contact with the radioactive material, and it doesn’t become radioactive itself. Think of it like getting an X-ray – you’re exposed to radiation, but you don’t become radioactive afterward.

Gamma radiation is different from other types of radiation you might be familiar with. For instance, X-rays, also on the electromagnetic spectrum, have lower energy than gamma rays and are commonly used for medical imaging. UV radiation, which comes from the sun, has even lower energy and can cause sunburns. It’s this high energy that makes gamma rays so effective at eliminating harmful organisms in food.

The Gamma Irradiation Process Explained

Now, let’s step inside a gamma irradiation facility. It’s a highly specialized place, designed to safely harness the power of gamma rays. Imagine a large, concrete room with thick walls – this is the irradiation chamber. At the center sits the radiation source, carefully shielded and contained. The food products, packaged and ready for treatment, are brought into the chamber, often on a conveyor belt or within a carrier.

Once inside, the food is exposed to the gamma rays for a specific period. The duration of the exposure, and therefore the dose of radiation, is carefully calculated and controlled. This process, known as dosimetry, ensures that the food receives the appropriate amount of radiation to achieve its intended purpose – whether it’s eliminating bacteria, killing insects, or extending shelf life. Think of it like baking a cake; you need the right temperature for the right amount of time to get the perfect result. Too little, and it’s undercooked; too much, and it’s burnt. Similarly, with gamma processing, the dose is precisely controlled to ensure effectiveness without compromising the food’s quality.

Here’s a crucial point to remember: the food never becomes radioactive during this process. The gamma rays pass through the food, depositing their energy, but they don’t leave any radioactive residue behind. It’s like shining a flashlight on an object – the light passes through it, but the object doesn’t become a flashlight itself. This is a common misconception about gamma processing, and it’s important to dispel it. The process is safe and doesn’t pose a radiation risk to consumers.

Common Gamma Processed Foods

So, what kind of food ends up getting the gamma ray treatment? You might be surprised to learn that a variety of foods are gamma processed to enhance their safety and quality. It’s not just some futuristic, lab-grown food; it’s stuff you probably eat regularly. Think spices, herbs, fruits, vegetables, grains, and even meat and poultry.

Here’s a peek at some common examples:

- Spices and Herbs: These are often gamma processed to eliminate bacteria like Salmonella and other pathogens that can lurk in them. Think about that paprika you sprinkle on your deviled eggs or the oregano in your spaghetti sauce – it might have been gamma processed.

- Fruits and Vegetables: Gamma processing can extend the shelf life of certain fruits and vegetables by delaying ripening and killing insects. Strawberries, for instance, are sometimes treated to keep them fresh longer. Potatoes and onions are sometimes irradiated to prevent sprouting.

- Grains: Gamma processing can be used to control insect infestations in stored grains like wheat and rice.

- Meat and Poultry: While less common than other food groups, meat and poultry can be gamma processed to reduce bacteria like E. coli and Campylobacter.

It’s important to note that not all foods are suitable for gamma processing. Some foods, like dairy products, can undergo undesirable changes in texture or flavor when exposed to radiation. The process is most effective for foods that are relatively solid and don’t have a high water content.

Now, how can you tell if a food has been gamma processed? Look for the radura symbol – that flower-like icon inside a circle we mentioned earlier. It’s the international symbol for food irradiation. In the US, gamma processed foods must also be labeled with a statement like “Treated by irradiation” or “Irradiated with gamma rays.” So, next time you’re at the grocery store, keep an eye out for the radura – it’s your clue that the food has received a dose of gamma ray goodness (or at least, treatment).

Benefits of Gamma Processing: More Than Just a Longer Shelf Life

Gamma processing offers a range of benefits that go beyond simply extending a product’s shelf life. It’s a powerful tool for improving food safety, controlling pests, and even delaying the ripening process in some fruits and vegetables. Let’s break down the key advantages:

-

Improved Food Safety: This is arguably the most significant benefit. Gamma processing effectively eliminates harmful bacteria like E. coli, Salmonella, and Listeria that can cause foodborne illnesses. These bacteria can contaminate food at any stage of the production process, from farm to table. Gamma processing acts as a final line of defense, ensuring that the food is safe for consumption. Think of it as a deep clean for your food, zapping those microscopic menaces that could make you sick.

-

Extended Shelf Life: By reducing spoilage-causing microorganisms, gamma processing can significantly extend the shelf life of many foods. This is particularly useful for products that are transported long distances or stored for extended periods. Imagine those spices sitting in your pantry for months – gamma processing helps ensure they stay fresh and flavorful.

-

Pest Control: Gamma processing is highly effective at killing insects and other pests that can infest food products. This is especially important for grains, dried fruits, and spices, which are susceptible to insect infestations. No one wants to find little critters crawling around in their flour or dried apricots, and gamma processing helps prevent that unpleasant surprise.

-

Delaying Ripening: For some fruits and vegetables, gamma processing can slow down the ripening process. This can be beneficial for extending their shelf life and preventing them from becoming overripe too quickly. Think of those perfectly ripe mangoes you buy at the store – gamma processing might have played a role in keeping them fresh and delicious.

-

Sterilization: In higher doses, gamma processing can be used to sterilize certain food products, as well as medical equipment. This means that all microorganisms, including bacteria, viruses, and fungi, are eliminated. This is particularly important for products used in hospitals and other healthcare settings.

Is Gamma Processing Safe? Addressing the Concerns

Now, let’s tackle the elephant in the room: safety. Gamma processing, because it involves radiation, understandably raises concerns for some people. But it’s crucial to separate fact from fiction. The overwhelming scientific consensus is that gamma processed food is safe to eat. Numerous studies conducted by reputable organizations like the FDA, WHO, and USDA have consistently shown that food irradiation, at the approved doses, poses no health risk.

Here’s a crucial point: gamma processing does not make food radioactive. We’ve touched on this before, but it’s worth repeating. The food is exposed to gamma rays, which pass through it, but they don’t leave behind any radioactive residue. It’s like getting an X-ray – you’re exposed to radiation, but you don’t become radioactive afterward.

The levels of radiation used in food processing are carefully regulated and are far lower than the levels that would pose a health risk. Think of it like sunscreen – you’re exposed to UV radiation from the sun every day, but using sunscreen protects you from the harmful effects of excessive exposure. Similarly, the radiation used in food processing is carefully controlled to ensure it’s effective at eliminating harmful organisms without compromising the safety of the food.

Some people worry about the formation of unique radiolytic products (URPs) during gamma processing. These are chemical compounds that can form when food is exposed to radiation. However, extensive research has shown that URPs are present in very low levels in gamma processed food and do not pose a health concern at the approved doses.

So, rest assured, the next time you see the radura symbol, you can confidently enjoy your gamma processed food knowing that it’s safe and has undergone a process that enhances its quality and safety.

Potential Drawbacks of Gamma Processing: A Balanced Perspective

While gamma processing offers numerous benefits, it’s important to acknowledge that, like any technology, it has potential drawbacks. It’s about weighing the pros and cons to make informed decisions.

-

Nutritional Changes: One potential drawback is that gamma processing can cause minor nutritional losses in some foods, particularly certain vitamins like thiamine (vitamin B1). However, these losses are generally minimal and comparable to those that occur during other food processing methods like cooking or canning. It’s not like your food is suddenly devoid of all nutrients; it still retains the vast majority of its nutritional value.

-

Unique Radiolytic Products (URPs): As mentioned earlier, URPs can form during gamma processing. While research indicates these are not a health concern at approved doses, some individuals may still have concerns. It’s important to note that many foods, even those not irradiated, contain naturally occurring chemical compounds, and the levels of URPs in gamma processed food are generally very low.

-

Cost: Setting up and operating gamma irradiation facilities can be expensive. This cost can potentially be passed on to consumers in the form of slightly higher prices for gamma processed food. However, the benefits of improved food safety and extended shelf life can often outweigh the slightly increased cost.

-

Public Perception: Despite the overwhelming scientific evidence supporting the safety of gamma processing, some consumers remain hesitant. This negative perception can be a barrier to wider acceptance of the technology. Education and clear communication about the science behind gamma processing are crucial to addressing these concerns.

It’s important to view these drawbacks in perspective. While there may be minor nutritional losses and some cost considerations, the benefits of improved food safety and extended shelf life often outweigh these concerns. And as for public perception, increased understanding of the science behind gamma processing can help alleviate fears and promote informed decision-making.